Jim Klinger, concrete construction specialist The Voice Newsletter August 2022

Question: We are bidding the concrete portion of a steel bridge job and noticed the term "bold exposure" mentioned in the Div. 5 construction documents. We aren't familiar with this term, and how it might affect our concrete scope.

Answer: The steel girders are called out to be fabricated with ASTM A588 weathering steel, also known as "COR-TEN" steel (taken from CORrosion-resistant, high TENsile strength). To oversimplify enormously, this material was developed to rust on purpose to protect itself from further rust. This idea works as long as the girder is “boldly exposed” to an environment that will allow a thin layer of rust to form on its outer surface. In this case, bold exposure means rain washed-sun dried. In reality, it probably takes several cycles of rain-wash and sun-dry before a protective oxide layer is fully formed. State highway departments typically specify weathering steel for girders and other steel members to eliminate initial painting cost and reduce future maintenance costs. Architects and artists use COR-TEN material for exposed steel buildings and sculptures because of the pleasing appearance of the patina. The key here is that weathering steel must be boldly exposed and allowed to dry. If that does not happen, then the whole plan backfires and the steel will corrode.

(N.B. #1: A notorious example of this is the Aloha Stadium in Honolulu which was built with COR-TEN steel in the 1970s. Many of the main structural members were designed such that they collected daily rainfall but were never allowed to dry. It was a disaster.)

For your project, the only "exposure" we see is a significant exclusion item related to the timing of your work and the follow-on placement of the steel. We suggest you exclude all work associated with rust stains that are likely to appear on any and all work you placed for the obvious reasons described above.

______________________________________________________________________________

Question: Does ASTM C856 explain what the w/cm ratio is in a core? I thought I remember reading an article at some point that said this was one of the things petrographic analysis could not show.

Answer: ASTM C856 Standard Practice for Petrographic Examination of Hardened Concrete recognizes that there are many factors that may influence the w/c and w/cm of the concrete paste, including amount of original water, free water introduced by aggregates, tempering and retempering water, bleeding and vibration after concrete placement, and so on. Section 13.3 states the following:

13.3 Because of the variable nature of pastes, age of pastes, and exposure to a variety of external influences, there is no generally accepted standard procedure that employs microscopical methods for determining the w/c or w/cm of hardened concrete.

The issue of petrographic analysis reports prepared to determine contract compliance was explored in some detail by Bruce Suprenant and Ward Malisch in an article titled "How to Evaluate Petrographic Reports...Separating Facts from Conclusions." It appears that estimates of w/c and w/cm might be made by some petrographers, but their reports and conclusions should always be carefully reviewed ...and possibly challenged.

(N.B.: During the course of researching this, we found one guide to petrography written by a certain state highway official who advises "The petrographer must use good judgement and a sense of justice in selecting the portion of the specimen" to be tested. Further guidance tells us his state department does not perform petrographic analysis "on samples suspected of having a normal or low water-cement ratio... we have never had to report a case where the cement content indicated that a significant excess of cement was added or that a significant amount of water was omitted.")

______________________________________________________________________________

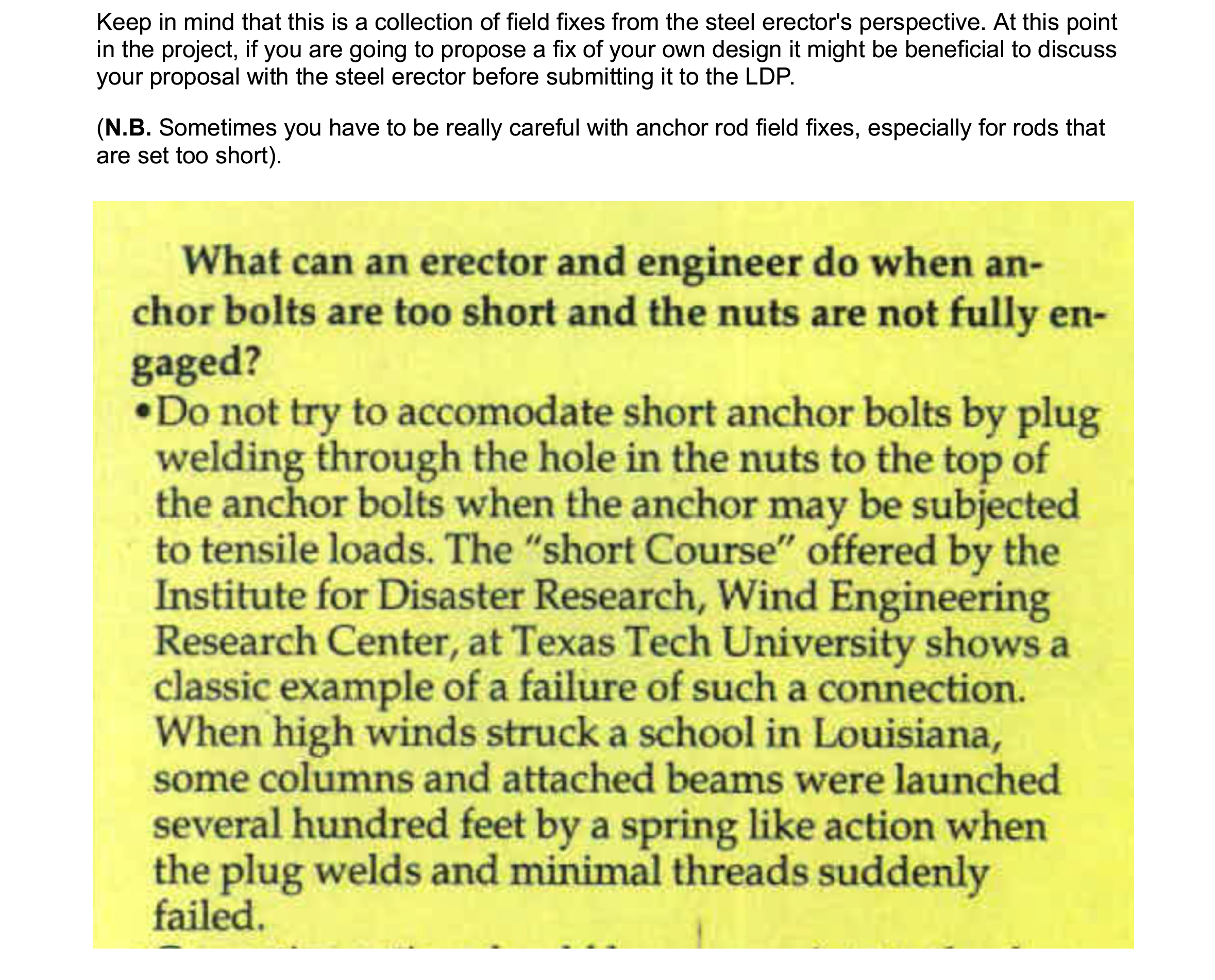

Question: We have misplaced a few anchor rods just outside the ACI-117 tolerance for anchor rod assemblies. We already know from discussing this with the steel erector that the fix will involve enlarging holes in the column baseplate and then welding plate washers to the baseplate after the column has been set. It is now on us to prepare a proposed fix submittal to the structural engineer for approval. Isn't there a "canned" collection of typical fixes for anchor rod mistakes like this?

Answer: As it turns out, the American Institute of Steel Construction (AISC) has several resources, many of them free, that are of value to ASCC members. In this case, there is an AISC document at this link titled "Field Fixes- Common Problems in Design, Fabrication and Erection- Solutions and Prevention."