JT Mesite, P.E., CRMCA & CTAC Program Manager

Edited by Mike Hernandez, ASCC Technical Director

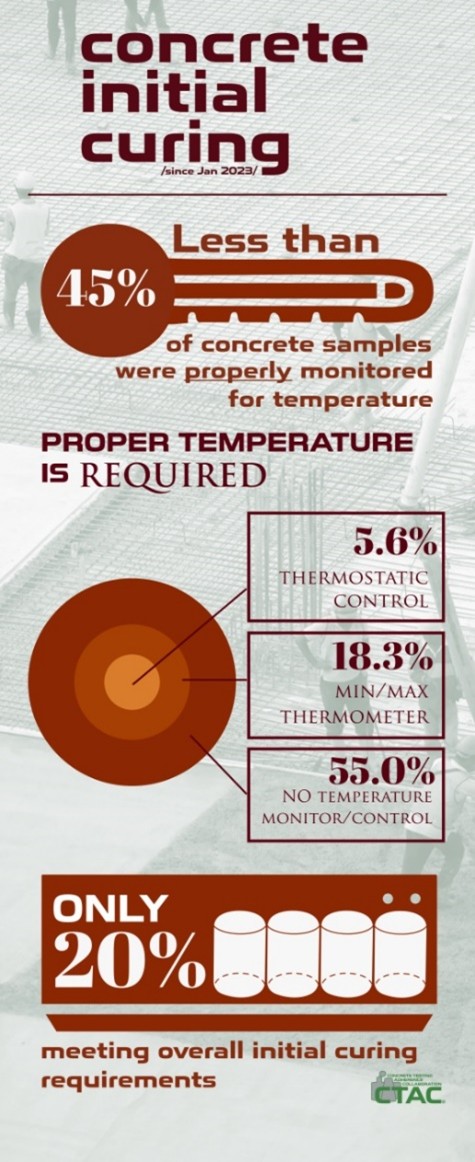

Concrete construction is an intricte process where quality control is paramount. Field testing must continuously meet specific ASTM requirements, and project concrete depends on maintaining precise temperature controls, effective initial curing processes, and a clear understanding of roles. The 2024 data indicates that ~80% of commercial projects do not meet all the ASTM standards for making and curing test clyinders. In most cases, testing and specimen evaluation are critical for quality assurance; they confirm that the material supplied by the concrete producer arrives on-site exactly as ordered and specified by the mix design. However, achieving this consistency is challenging. Variability in testing procedures, curing facilities, and monitoring conditions, as well as fragmented communication among project stakeholders, can lead to discrepancies that ultimately affect a project’s success. The Colorado Ready Mixed Concrete Association (CRMCA) and ASCC have entered a collaboration to support proper concrete testing. If you prefer to listen to a summary of the CTAC solution, Todd Ohlheiser, CRMCA Executive Director, was recently interviewed on the Concrete Logic Podcast, posted to YouTube: https://youtu.be/FwtwkV32KGY

The Project-Level Challenges

Every construction site faces the critical task of ensuring that concrete samples and testing adhere consistently to ASTM requirements. Field testing isn’t just a formality, it is the backbone of a project’s quality assurance. One of the most important phases is the initial curing process, which is essential for long-term strength and durability. In many projects, specimens undergo either a standard cure or a field cure. Standard cure is focused on verifying the concrete’s quality per the mix design, while field cure is generally applied when removing forms or opening areas for traffic. Often, inadequate temperature control and facility limitations during standard curing can compromise the process and is the most frequenelty violated early test. The specifications outlined in ACI 301 and ACI 318 place a shared responsibility on all parties involved, demanding continuous oversight and proactive communication. When pre-construction meetings and regular team discussions fail to bridge the gap between planning and on-site realities, delays, rework, and compromised structural integrity can result.

Empowering On-Site Teams with the CTAC App

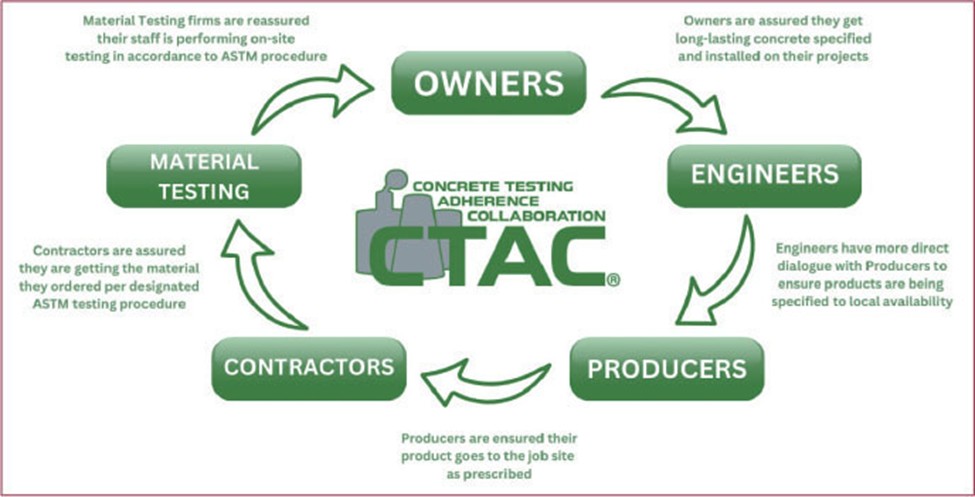

Enter the Concrete Testing Adherence Collaboration (CTAC) program, a comprehensive solution designed to address these challenges. CTAC brings together observation, review, and reporting tools into a single platform, providing the ability to collect observation data into a collective dashboard. This actionable data not only improves testing consistency but also fosters ongoing dialogue among team members throughout every phase of a project.

Observation: Capturing Critical Data in Real Time

The observation module is the foundation of CTAC, empowering field personnel to capture vital testing data as conditions unfold on-site using the CTAC phone app. Key features include:

- GPS Integration and Offline Capability: Every observation is accurately geotagged and securely saved, even in areas with unreliable internet connectivity.

- User-Friendly Interface: The interface simplifies data entry so that every Observer, certified as an ACI Concrete Field Testing Technician Grade I, can efficiently record essential metrics consistently. It also allows the observer to note any inconsistencies while the testing technician performs procedures and capture supporting photos or short videos, ensuring immediate, open communication on-site.

- Daily Initial Curing Checklist: Perhaps the most transformative feature is the initial curing review module, which is the most often violated ASTM standard based upon thousands of observetions and can negatively effect cylinder strength by up to 20%. Unlike the more complex field-testing observations that require ACI certification, this tool serves as a daily checklist item that any trained contractor can use. By routinely verifying that initial curing conditions meet ASTM standards, teams can identify potential issues early, sparking timely conversations during construction meetings or daily briefings that keep every stakeholder informed. The training process involves watching a ~ 5 minute video and answering a 6 question test to confirm understanding.

Review: Validating Data and Enhancing Training Once data is captured, the review module acts as a vital quality checkpoint where project leaders can assess performance, address issues, and celebrate outstanding teamwork:

- Data Validation and Error Flagging: Supervisors can quickly verify observations, with the system automatically highlighting inconsistencies that warrant further attention.

- Enhanced Training Opportunities: Feedback from the review phase has spurred the development of specialized training modules, particularly focusing on improving initial curing practices. Although observations collected in the past two years show that only about 20% of samples meet the ideal curing conditions, this statistic is viewed as an opportunity to refine techniques and boost overall quality.

- Seamless Integration: The review process works in tandem with the observation and reporting tools, ensuring a smooth flow of information that supports continuous learning and encourages ongoing discussions among team members.

Reporting: Turning Data into Strategic Insights

The reporting module transforms raw data into actionable insights that drive better decision-making:

- Customizable Dashboards: Project managers and stakeholders can generate reports tailored to specific needs, whether for daily operations, project reviews, or high-level strategic planning.

- Real-Time Access: Up-to-date information is readily available, empowering teams to address issues proactively and maintain project momentum.

- Scalable Insights: From monitoring individual projects or employees to assessing regional or nationwide trends, the reporting tool provides a comprehensive view that supports both immediate improvements and long-term planning. These insights serve as conversation starters during team meetings, pre-construction reviews, and strategy sessions, further embedding open communication into the project workflow.

Addressing Adoption Challenges and Shaping the Future

Despite its many advantages, the CTAC app has faced its share of hurdles. Early on, some testing firms misconstrued CTAC as a surveillance tool rather than a collaborative platform for quality improvement, which created resistance among certain entities. However, through ongoing dialogue and the sharing of success stories, often discussed during regular project meetings, perceptions are shifting. Contractors are increasingly recognizing CTAC for its true value in enhancing communication and bolstering quality control on-site.

The onboarding process initially presented its own set of challenges, with users needing time to adjust to the new system. In response, CTAC is overhauling its training resources. Each module now provides clear guidance on using the observation, review, and reporting features, ensuring that even newcomers can quickly become proficient. This educational focus is particularly vital in reinforcing the daily use of the initial curing review as a simple yet effective tool to safeguard concrete quality while keeping the lines of communication open among all team members.

A Vision for Nationwide Impact

Looking ahead, CTAC is poised to revolutionize concrete testing on every scale, from single projects to regional and ultimately nationwide operations. Recent changes, such as the shift from Partner-based to Company-based logins, aim to streamline data submission and broaden access, with users across the country contributing to a centralized database of nearly 2,500 field observations in the past 12 months.

Continued Collaboration

We invite every ASCC contractor to participate that works in a state who has joined the CTAC program (AL, CA, CO, GA, IA, MN, ND, TX, WA, WI & Ontatio Canada) which represent ~ 40% of the U.S. population. ASCC Contractors can join as a full observer if they have current ACI Concrete Field Testing Technican Certification. To request Observer access to the CTAC program scroll to the bottom of the page here: https://www.concretetac.com/member-login/ and fill out the form.

The other option is to watch one ~ 5 minute video plus a 6 question exam to become an Initial Curing Reviewer. If you want to become an IC reviewer folow this link and click on “Start now”: https://forms.office.com/pages/responsepage.aspx?id=l21lIvFqD0yCep-tIjfx2wq9PHc1nkxCrQ5gGJnk4_RUNzJOWUZHRDJBQ0NVT1JZWkZYSVhGR1VYWiQlQCN0PWcu&route=shorturl

For further information, assistance, or to share your feedback, please contact us at ctac@coloradocaa.org or visit our website at www.concretetac.com. Your participation is the key to our collective success in transforming the industry.