Bruce Suprenant, Technical Director, The Voice Newsletter December 2017

ACI 306R-88, “Guide to Cold Weather Concreting”, addressed multiple cycles of freezing and thawing by recommending that the concrete reach a compressive strength of 3500 psi prior to that exposure. ACI 201-77, “Guide to Durable Concrete”, also addressed the issue by stating: “Before being exposed to extended freezing in a severe exposure, it is desirable that concrete attain a specified compressive strength of 4000 psi. For moderate exposure conditions, a specified strength of 3000 psi.” ACI 308R-01, “Guide to Curing Concrete” stated that “Air-entrained concrete should not be allowed to freeze and thaw in a saturated condition before developing a compressive strength of 3500 psi.”

These three ACI documents have the following in common:

- None of them include references to data from research done to document the need for compressive strengths ranging from 3000 psi to 4000 psi.

- The recommendations still exist in the current committee documents.

Some specifiers require a design strength (f’c) of 3000 psi for air-entrained concrete that might never achieve the recommended compressive strengths before being exposed to multiple freeze-thaw cycles. Based on research by Timms and Withey, it would take about 28 days to reach 3500 psi at 50F with a water-cement ratio of 0.53 and a cement content of 500 to 525 lbs./cy. We don’t see contractors using insulating blankets for 28 days and we don’t see any freeze-thaw failures. However, we are seeing inspectors citing the 3500 to 4000 psi recommendation and requiring that contractors protect the concrete until a maturity meter shows the appropriate strength. This is taking weeks.

The question is which is correct: the ACI documents recommending 3500 to 4000 psi, or our observations of no freeze-thaw failures when contractors protect the concrete with insulating blankets for only 3 to 7 days? We started looking for data and found an article by Klieger titled “Further Studies on the Effect of Entraining Air on Strength and

Durability of Concrete with Various Sizes of Aggregates”—originally published in 1958 and republished in ACI Concrete International in November 2003.

The prism-shaped specimens used in the freezing and thawing tests were cured 1 day in the molds, 13 days in the moist room, 14 days in the laboratory (50% relative humidity) and then 3 days in water prior to the start of tests. Two complete cycles of freezing and thawing were obtained every 24 hours, the prisms being immersed in tap water at all times. The rate of cooling was about 20F per hour. Periodic determination of changes in weight, expansion and sonic modulus were used as criteria for durability.

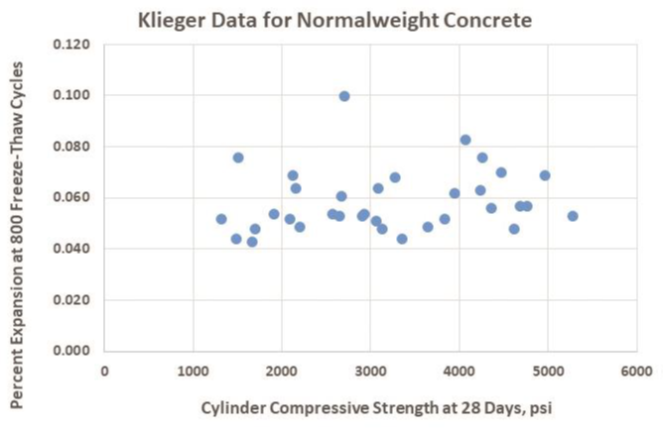

We used Klieger’s data to plot the following graph of expansion versus compressive strength. Higher expansions indicate lower quality concrete, with 0.1% expansion being considered the failure point. Freeze-thaw tests usually consist of 300 cycles, but Klieger extended expansion measurements to 800 freeze-thaw cycles specimens that had not yet reached 0.1% expansion. Based on the compressive strength recommendations for concrete exposed to multiple freeze-thaw cycles, we expected failures at concrete below 3500 or 4000 psi. However, concretes with compressive strengths as low as 1500 psi performed well for 800 freeze-thaw cycles. Someone needs to show us the reference that supports ACI recommendations. We don’t think it exists.