Tom Pelo, Jeff Huff, Tarek Khan, and John Luciano (Retired) Master Builders Solutions Admixtures US LLC – June 2025

Introduction

Given the recent interest in low-embodied carbon concrete (LECC), there are new cementitious materials, multiple supplementary cementitious materials (SCM) and admixture chemistries available to reduce the embodied carbon content of concrete. For example, Type IL cement was recently introduced in most US markets. These materials can affect the performance of concrete negatively, especially with respect to setting times and strength development. Master Builders Solutions has developed a procedure using concrete mortars to quickly evaluate combinations of raw materials to assess their performance that is based on ASTM C1810, Standard Guide for Comparing Performance of Concrete-Making Materials Using Mortar Mixtures, particularly, “Method A, Mortar Proportioned Based on Job Concrete Mixture Proportions”1. The information gained from this small-scale, assessment procedure can be used to quickly screen multiple combinations and reduce the requirements for large-scale concrete testing.

Following are procedures and testing protocols that have been used by Master Builders Solutions personnel and others in the lab and the field. Typically, the procedure requires only ten minutes to complete a single batch. In addition to physical tests on the mortar, calorimetry and maturity testing establish broad differences in setting time and strength development performance. Others have done similar work and found reproduceable results on a consistent basis.2

Guidance

It’s suggested that a thorough testing plan be developed that addresses the project’s concrete requirements, for example high-early strength, setting-time needs, and longer- term strength development. It’s imperative to use locally available concrete sands due to the high variability of aggregate properties that affect water demand and strength, for example cleanliness, soundness, and clay content. This in contrast to ASTM test methods for testing the strength of cements made with mortar containing ‘standard sand’, i.e., “Ottawa” sand. Concrete sand has an influence on concrete properties, especially the required water content to make workable, placeable concrete before the addition of water- reducing admixtures. Consider the workability requirement for the concrete; for example, will the concrete be pumped, will it be flatwork that’s finished by hand or machine-troweled, or will it be placed in a form? Each requires a different water content and water-reducing admixture combination.

Early indications of each of these properties can be established following this procedure. The moisture content of the sand should be determined immediately prior to testing so that

the added water content can be adjusted based on the SSD specific gravity and the measured moisture content.

This procedure is typically run at 70°F but it can be run at the anticipated concrete temperature by adjusting the temperature of the mixing water, the sand, and cementitious materials.

Plan on batching approximately 0.35 ft3 of mortar. This batch will yield enough mortar for ten 3 X 6-inch test cylinders or four 4 X 8-inch cylinders with sufficient materials to run a mini-slump3 and 0.5L mortar meter.4 Batches could be mixed in a Hobart mixer as outlined in ASTM C1810, which requires multiple batches for larger quantities.

Procedure

- Pre-weigh the sand in a 5-gallon bucket.

- If necessary, pre-cool or pre-heat the sand using a refrigerator or hot plate to match the anticipated concrete temperature.

- If needed, add the air-entraining admixture on top of the sand.

- Pre-weigh cements and SCMs in a 3-gallon bucket.

- Pre-weigh water and water reducing admixture(s) in a separate bucket.

- If necessary, adjust the water temperature using ice or hot water, to match the anticipated concrete temperature. For extreme temperatures, the sand and cementitious materials can be pre-cooled or pre-heated to achieve the anticipated concrete temperature in production and placement.

- Mixing procedure:

- Dump the cement (and any SCMs) on top of the sand in a 5-gallon bucket. Immediately add water with chosen admixture dosage

- Mix at medium to high speed with the Milwaukee Mud Mixer5, for 60 to 90 seconds.

- Scrape sides of bucket to ensure all materials are thoroughly mixed.

-

Measure the temperature of the prepared mortar.

-

Perform the mini-slump/spread test based on the desired mortar consistency.

-

Perform the air test with mortar air meter6.

-

Fabricate the required number of 3 X 6-inch cylinders for compressive strength testing.

-

Store the cylinders in the Calmetrix, F-Cal calorimeter7 and EXACT Technology Match Curing chamber 8 as indicated in the testing plan.

-

Perform the thermal indication of set (TIS) using the Calmetrix, F-Cal calorimeter7.

-

Break the test cylinders at times that match the project requirements, for example 12 hours, 1-day, 2-days, etc.

-

Correlate the compressive strength test results with the data from Calmetrix and EXACT Match equipment.

-

Develop the maturity curve using the appropriate EXACT Technology equipment8.

About Calorimetry

The reaction between cement and water (called ‘hydration’) is exothermic, that is, it generates heat. By measuring the heat outflow using a calorimeter, which tracks the temperature of the hydration reaction, one can understand the behavior of concrete or mortar. Simple set time or compressive strength tests do not show this much information. Calorimetry measurements will indicate the effectiveness of admixtures on the hydration reaction, thereby allowing decision makers to optimize cement, SCM and admixture combinations for a given project’s specific needs. The data generated by the thermal indication of set (TIS) measurements allows us to predict initial and final setting times (i.e., the ‘finishing window’) for a given combination of materials. In our experience, the F-Cal 8100 semi-adiabatic calorimeter provides the functionality and ease of use for lab or field testing for concrete tests. The Calmetrix team is supportive and can further explain the use of their equipment. For more information, visit: https://www.calmetrix.com/ Note that the recommended equipment follows ASTM C1753 "Evaluating Early Hydration of Hydraulic Cementitious Mixtures Using Thermal Measurements".9 The F-Cal 8100 unit is described here: https://www.calmetrix.com/f-cal-calorimeters There’s a link called “Concrete Testing” at the bottom of that page to multiple short videos and an hour-long webinar on the Calmetrix YouTube channel. Consult Calmetrix for cost information and the hardware requirements for the laptop computer or tablet needed to capture data.

About the Maturity Concept

The maturity concept utilizes the same premise that calorimetry uses; namely that the hydration reaction generates heat. According to the National Institute of Standards and Technology, “the maturity method is a technique to account for the combined effects of time and temperature on the strength development of concrete. The method provides a relatively simple approach for making reliable estimates of in-place strength during construction.”10 The method depends on establishing an accurate calibration curve by casting enough cylinders to determine the strength of concrete over time, typically 12 to 72 hours, and then ‘matching’ those strengths to the measured time-temperature data. Future concrete placements will not require cylinders to be cast and broken; rather the time- temperature data is collected and recorded using temperature sensing equipment. More detailed information about the maturity method can be found in ACI 228.1R-19, “Report on Methods for Estimating In-Place Concrete Strength”.11 There is an ASTM practice for estimating strength using the maturity method.12 A simple discussion of using the maturity method is presented in “Concrete in Practice 39 Maturity Methods to Estimate Concrete Strength”.13 The engineers that founded EXACT Technology come from the concrete construction industry and can explain the maximum effectiveness of this concept. For more information, visit https://www.exacttechnology.com/ Consult EXACT Technology for cost information and the hardware requirements for the laptop computer or tablet needed to capture data.

About Master Builders Solutions

We offer advanced chemical solutions for new concrete construction and underground construction in the U.S. and Canada. Our brand is built on more than 100 years of experience in the construction industry. Our comprehensive portfolio encompasses concrete admixtures, cement additives, macro, and microfiber reinforcement for concrete and chemical solutions for underground construction. To solve our customers’ specific construction challenges from conception through to completion of a project, we draw on our specialist know-how, regional expertise and the experience gained in countless constructions projects worldwide. We leverage global technologies, and our in-depth knowledge of local building needs to develop innovations that help make our customers more successful and drive sustainable construction.

Master Builders Solutions Admixtures own lab in Cleveland, Ohio is available to provide services for concrete producers and contractors. Find a local Master Builders Solutions representative by using the link at the bottom of this page: https://master-builders- solutions.com/en-us/contacts/

Alternately, you may contact the authors.

Tom Pelo is a Development Manager, based in Montana, who works across the Western United States. Reach him at tom.pelo@masterbuilders.com

Jeff Huff is a Senior Territory Manager in Western Washington and Northwestern Oregon. Reach him at jeff.huff@masterbuilders.com

Tarek Khan is a Business Development Manager, in Master Builders Solutions Admixtures’ Concrete Sustainability Group. He is based in California and works across the United States. Reach him at tarek.khan@masterbuilders.com

John Luciano is retired from the Master Builders Solutions, having worked in the research and development group in Cleveland, Ohio for over 40 years.

Footnotes

- ASTM C1810 “Standard Guide for Comparing Performance of Concrete-Making Materials Using Mortar Mixtures”, published by ASTM International, available here: https://www.astm.org/

- “Laboratory Paste Mixtures as a Concrete Mix Design Tool”, an American Concrete Institute Web Session presented by Tim Cost, available here: https://www.concrete.org/publications/getarticle.aspx?m=icap&pubid=51686537 (free to ACI members) and “Mortar Testing for Estimating Strength”, by Joseph J. Daczko, Published in Concrete International, by the American Concrete Institute, September 1999, available here: https://www.concrete.org/publications/internationalconcreteabstractsportal.aspx?m=det ails&id=277 (free to ACI members)

- ASTM C1437 “Standard Test Method for Flow of Hydraulic Cement Mortar”, published by ASTM International, available here: https://www.astm.org/

- ASTM C185 “Standard Test Method for Air Content of Hydraulic Cement Mortar”, published by ASTM International, available here: https://www.astm.org/

- “Milwaukee M18 Fuel 18V – ½-inch Mud Mixer”, available from Milwaukee Tool https://www.milwaukeetool.com/Products/2810-22

- “Humboldt Mortar Air Meter”, available from the Humboldt Construction Materials Testing Equipment https://www.humboldtmfg.com/air-entrainment-meters-for-mortar- actual.html

- “F-Cal 8100 Portable semi-adiabatic calorimeter” (requires software installation and suitable computer), available from Calmetrix https://www.calmetrix.com/

- “EM1” or “EM2” Curing chambers (requires software installation and suitable computer), available from EXACT Technology https://www.exacttechnology.com/

- ASTM C1753 "Evaluating Early Hydration of Hydraulic Cementitious Mixtures Using Thermal Measurements", published by ASTM International, available here: https://www.astm.org/

- “The Maturity Method: from Theory to Application”, by N.J. Carino and H.S. Lew, published by The Building and Fire Research Laboratory at the National Institute of Standards and Technology. This document is in the public domain here: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=860356

- ACI 228.1R-19, “Report on Methods for Estimating In-Place Concrete Strength”, published by the American Concrete Institute, available here: https://www.concrete.org/store/storeresults.aspx?Keyword=228.1

- “ASTM C1074 “Standard Practice for Estimating Concrete Strength by the Maturity Method”, published by ASTM International, available here: https://www.astm.org/

- “Concrete in Practice 39 Maturity Methods to Estimate Concrete Strength”, published by the National Ready Mixed Concrete Association, available here: https://www.nrmca.org/wp-content/uploads/2021/01/39pr.pdf

Mortar to Mix Procedure – Equipment List

Typical setup – 5-gallon bucket (not shown)

Milwaukee M18 Fuel 18V – ½” Mud Mixer – Available here: https://www.milwaukeetool.com/Products/2810-22

Mud Mixer Paddle – Dual Stage 5” wheels – Available here: https://www.krafttool.com/DC310?srsltid=AfmBOopiVd1raLF_JmUP1WnmHuVN_8ivrdvJY ZJ22Rrj5LfLoz1jWXB7

Digital Temperature Gun – accurate to 0.5 degrees F Electronic Calipers – accurate to 1 mm

5” Mortar Cone – Available here: https://www.americancubemold.com/Mini-Steel-Slump- Cone-p/acm-32mn.htm

Plexiglass sheet 24” X 36” – 1/8”

3” by 6” and 4” by 8” Plastic Cylinder Molds (not shown)

Prepared Mortar – Entrained Air Analysis

Prepared mortars are tested with .5-liter mortar air meter to determine entrained or entrapped air content, such as the Humboldt Mortar Air Meter – H-2847 - .5L Mortar Air Meter Available here: https://www.humboldtmfg.com/air-entrainment-meters-for-mortar-actual.html

Calorimetry Testing – Thermal Indication of Setting Characteristics

F-Cal 8100 semi-adiabatic calorimeter connected to a laptop

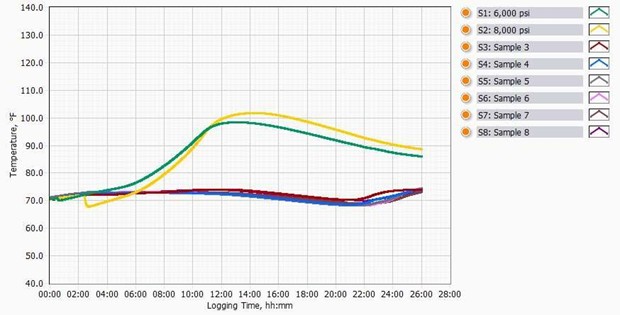

Sample heat of hydration curve

Prepared mortar samples in 3”X6” plastic cylinder molds are placed into the Calmetrix F- Cal 8100. Up to 8 prepared mortars can be tested simultaneously. Heat of hydration is measured and can then be converted into analysis logs for estimating setting times and strength prediction.

More information is available at: https://www.calmetrix.com/f-cal-calorimeters

Maturity Curve Testing – EXACT Technology Equipment

EM1 Match Cure Box

The EM1 unit enables cylinder curing to match temperatures of in-place concrete. Data loggers with attached probes are inserted into concrete member. The temperature is measured and relayed to the curing box, which cures cylinders at the same temperature as the in-place concrete members.

EM2 Match Cure Box

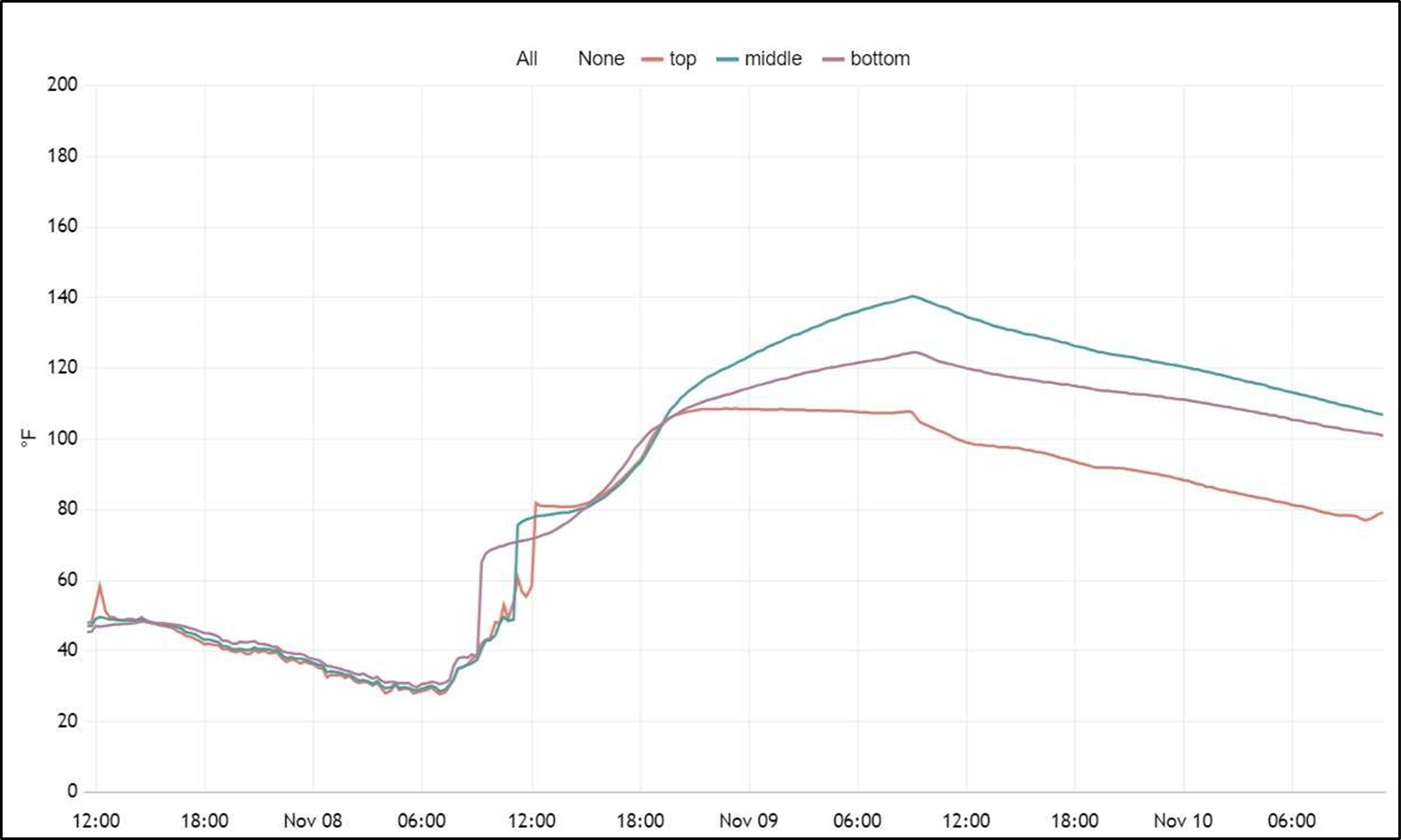

The EM2 Match Curing unit is a programmable curing box capable of curing cylinders at temperatures ranging from 40 to 140 degrees F. Temperatures can be held constant or can be varied. The EM2 provides time-over-temperature graph, which can be combined with compressive strength information, to formulate maturity curves based on the data.

More information is available at https://www.exacttechnology.com/

Sample Calorimetry Data

Sample Maturity Data