Jim Klinger, Concrete Construction Specialist

The Slab Newsletter May 2025

Question: We have been asked by the general contractor (GC) to place cementitious slurry backfill in a MEP (mechanical, electrical, plumbing) trench containing a group of 2-inch diameter CPVC (chlorinated polyvinyl chloride) pipes. Our scope of work is to pump, place, and finish cementitious slurry to cover CPVC piping that has been excavated, furnished, and installed by others. The trench dimensions are 2.5 ft. wide, 4 ft. deep, and 130 ft. in length-- which translates roughly into a 49 CY (cubic yard) placement.

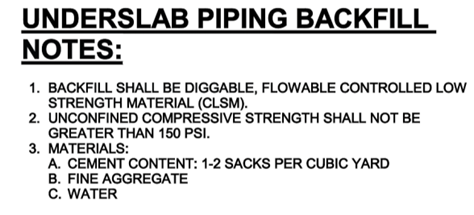

The construction documents present the typical requirements for backfill at MEP trenches as follows:

In addition to the above stated backfill requirements, the following review comments were extracted from the approved CPVC material submittal prepared by the MEP subcontractor and forwarded to us by the GC:

"Contractor to submit backfill mixture that limits heat of hydration to less than 220 degrees F. Submit records that document--during backfill and curing--that the temperature remains below 220 degrees F. If temperatures reach or exceed 220 degrees F, piping must be removed and replaced".

Following the above criteria, our readymix supplier prepared a mix design for submittal titled "2-Sack Sand Slurry" with the following per-cubic-yard proportions: Type II/V cement: 188 pounds. Water: 517 pounds (62 gallons). Sand: 2803 pounds. Total weight per cubic yard: 3508 pounds. Unit weight: 130 pounds per cubic foot (pcf). Slump: 5 inches, plus or minus 2 inches. No admixtures were specified or included.

Unfortunately, our readymix supplier is unable to find on file any historical data (thermal or compressive strength performance) to furnish as backup for their 2-sack sand slurry mix.

So we attempted--on our own--to find documentation that would help us predict the maximum heat of hydration for the proposed mix. It turns out that the available concrete industry thermal formulas and models all seem to be based on mixes with much more cement content than ours; and with larger concrete member dimensions than ours. Put another way, it turns out that our proposed slurry mix is too lean-- and the trench is too small--to be considered "mass concrete"--and therefore cannot be considered as a realistic cause for concern.

At this point, the questions then became: "Given our cementitious slurry mix containing 188 pounds of Type II/V cement per cubic yard, what would the thermal performance likely to be during the first few days after initial placement of the slurry? How long will it take for the in-place slurry to attain maximum temperature after placement?

After much research and in-house, jobsite trailer debate, we advised the project Owner that it is not possible for the proposed 2-sack slurry to reach a temperature of 220 degrees F during the curing period. In fact, we actually anticipate the curing temperatures to be well under 100 degrees F. We are looking to the ASCC Hotline to take the temperature of this situation and weigh in.

Answer: Interesting question. As concrete contractors, the Hotline doesn't field many questions like this, since backfilling of MEP trenches is typically performed by others before our members mobilize onsite and take ownership of the prepared building pad. Nevertheless, this scenario highlights risks associated with incidental concrete work that ASCC members may eventually be asked to take on.

Consistent with the ASCC Hotline's long-standing M.O. (modus operandi), we typically recommend Hotline callers try to have a look at the other guy's playbook. After all, according to the CVPC pipe supplier's stated upper limit of 220 degrees F, the backfill slurry could be at the boiling point of water after placement and still be acceptable (water boils at 212 degrees F), with 8 degrees F to spare.

We began our playbook literature survey by reviewing a technical brief prepared by the PVC Pipe Association titled "PVC Pipe In Contact With Concrete" and dated 7 May 2021, which explains:

"During the concrete curing process, heat is generated (known as "heat of hydration"). The vast majority of installations experience no issues with excessive heating. If this is a concern, choosing concrete formulations with low heat of hydration is the most common solution. Another option is to dissipate heat by filling the pipe with water (essentially creating a heat sink) until the concrete has cured."

A similar Technical Bulletin found in an industry pipe manufacturer's playbook titled "Best Practices for Concrete Encasement of PVC and CPVC" addresses potential topics such as how to prevent flotation of PVC pipes during placement of concrete, why it is best to limit the maximum depth of cover over the pipes to 2 feet, and preventing damage that might be caused to the pipes by mechanical vibrators during slurry placement. Regarding potential thermal damage, the Technical Bulletin offers the following guidance:

"During the curing process of the concrete, temperatures within the concrete may very well rise above the ambient temperature conditions. Care should be taken to prevent the piping system from experiencing temperatures above 140 degrees F. Although the idea of blowing cold air through the piping system might achieve the required temperature control, another option is to consider filling the piping system with cold water. The cold water would act as a thermal heat sink."

In the course of our literature review, we found an industry report describing potential heat of hydration issues associated with lightweight cellular concrete (LCC) used in certain backfill applications. A recent Portland Cement Association document (Guide to Lightweight Cellular Concrete for Geotechnical Applications, January 2021) reports the following:

"LCC is comprised of portland cement, water, and air (added through a preformed foaming agent). The curing of cement is an exothermic reaction, commonly known as the heat of hydration. This rapidly occurring chemical reaction has been known to generate temperatures above the boiling point of water. Under normal conditions, the heat of hydration in an LCC fill begins two to four hours after placement...The heat of hydration can be a significant problem when placing plastic pipes within large masses of LCC undergoing curing and should always be considered when designing an LCC fill. While an LCC fill will always warm up, placement with an open top will not obtain the maximum heat forecasted, which assumes no heat loss and represents the highest temperatures possible. Internal temperatures in large flat fills typically range from 100 to 150 degrees F."

Based on the above, we can see why the CPVC pipe supplier would raise the issue of potential damage caused by cementitious heat of hydration. Next step: we have the approved mix design for the slurry in hand, but the readymix supplier lacks any historical temperature performance data for us to use as backup. Where do we go from here?

Following the Hotline caller's lead, we searched the ASCC Technical Division library facilities for information that might help us predict (and monitor) the heat of hydration for a lean slurry backfill mixture. The closest information we could find was all related to American Concrete Institute (ACI) and other industry publications that discuss mass concrete and describe preparation of thermal plans typically required for projects featuring mass concrete.

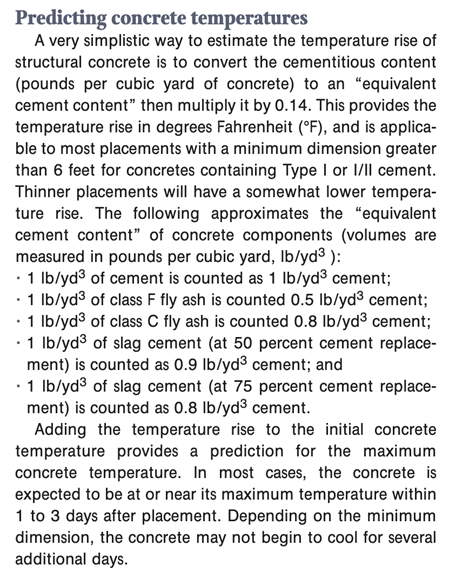

Out of all the documents and articles that we located, perhaps the best suited for our purposes is a PCA publication titled "Engineering Mass Concrete Structures", part of the Professional Development Series for continuing education. Authored by John Gajda and Ed Alsamsam, this 2006 publication offers the following guidance that explains one easy way to predict concrete temperatures:

Based on the procedure described above, the ECC factor for the trench backfill turns out to be the same as the actual cement content, which--in our case--is 188 pounds per cubic yard. The predicted rise in temperature, then, is calculated by multiplying the ECC by 0.14 as described above--which results in a temperature rise of 26.32 degrees F (rounded down to 26 degrees F).

The next step is to add the expected temperature rise to the temperature of the concrete as delivered. If we assume the temperature of the slurry at delivery is 75 degrees F, then the maximum predicted temperature would be the sum of 26 plus 75, or a total of 101 degrees F-maximum.

(N.B.: The ECC factor for "straight" cement is reckoned in the above PCA procedure on a 1-to-1 basis. Fly ashes and slag, on the other hand, contribute less to the heat generated by the mass, so their respective ECC factors are reduced to suit. The lowest ECC factor presented above is for Class "F" fly ash-at 0.5 percent-a pozzolan popular in concrete mixes that offer reduced short-term heat of hydration in exchange for slower, long-term time needed to reach design compressive strength. We have experience with at least one successful foundation mat slab mix featuring Class F fly ash that was designed to reach the required compressive strength at 120 days).

Keep in mind that the PCA method presented above is valid for concrete with certain minimum dimensions and a certain minimum cement content per cubic yard. As reported by the Hotline caller and described above, the proposed slurry mixture is so lean--and the dimensions of the trench are so small--that we find ourselves outside of the extreme lower limits of what could reasonably be considered mass concrete. In any event, it seems fair to say that the 101-degree F temperature calculated above falls on the conservative side, and very close to the "well under 100 degrees F" temperature advertised by the Hotline caller to the project stakeholders.

JOBSITE UPDATE: As scheduled, the slurry backfill was placed last weekend, with placement starting at 1:30 AM. The slurry was placed with a trailer pump featuring 50 feet of rubber hose "system". Temperature sensors were placed in the slurry at three locations along the MEP trench; each sensor was located 4 inches below top of slurry elevation. According to the reports generated by each of the three sensors, the average slurry temperature at delivery was 61 degrees F. The average maximum temperature inside the slurry mass--at an average of 16 hours after placement-- was measured at an average of 76 degrees F. Using the PCA formula described above, and using a temperature at delivery of 61 degrees F, the result predicts a maximum temperature of almost 86 degrees F; which--given the lean mix and small sample size--a conservative answer is no surprise.