Jim Klinger, Concrete Construction Specialist

The Slab Newsletter April 2025

Question: We are building a 4-story, post-tensioned (PT) concrete parking structure that has a footprint area of 75,000 gross square feet (GSF). The structure has a long, rectangular aspect ratio (in plan), featuring entrance/exit ramps at each end. The plan dimensions are 600 linear feet (LF) in length and 125 LF in width.

Since the PT structure is expected to shorten due to the application of PT forces, and would be susceptible to thermally induced movements (e.g. expansion and contraction) due to its length, an expansion joint was placed by the structural engineer which bisects the structure into two equal 300 LF sections. For all practical purposes, introduction of the expansion joint results in two separate buildings; each with plan dimensions of 300 LF long by 125 LF wide.

The specified concrete compressive strength is 3000 psi at 3 days (for PT stressing purposes) and 5000 psi at 28 days. All the ready-mix suppliers in our area have developed similar, off-the-shelf mixes to satisfy these so-called "high-early" compressive strength performance requirements.

There are two floor finishes specified for the 8-inch-thick PT slabs; namely a trowel finish in small areas in front of the elevator bank and in mechanical rooms, and a swirl finish for the balance of the work, including drive lanes, parking stalls, and ramps. And speaking of ramps, that is why we are calling the ASCC Hotline.

The ramps in this garage are 30 feet wide. Since the "high-early" concrete has performed as advertised, our PT stressing operations have been both efficient and uneventful--until our stressing crew pulls the short tendons at the ramps. We can't seem to get the 30-foot tendons to elongate within the allowable tolerance of plus/minus 7 percent of the theoretical elongation--as calculated by our PT supplier--and included in our (now approved) PT shop drawing submittal. For example, the theoretical elongation should be around 2 3/8 inches. We are averaging measured elongations of say 2 3/16 inches.

On this project, the structural engineer of record only provided the required tendon forces on the floor plans (aka required effective force, after all losses). From those plans, it was then our responsibility to hire a licensed engineer to calculate the number of unbonded PT tendons (e.g. uniform, banded, temperature) needed to supply the engineer's required effective forces; and then provide supporting calculations that indicate the theoretical lengths that each tendon should elongate to when stressed to the appropriate jacking force. When completed, the PT submittal had to be reviewed and approved not only by the structural engineer--but by the City Building Department plan check engineer as well.

In our experience, we have built several PT garages with ramps, and have never had problems with the short tendon pulls. According to our project specifications, we cannot cut the stressed tendon tails and complete the corrosion protective encapsulation system (e.g. "cut--grease--cap--grout") until the PT elongation records have been approved.

We understand the tendon finishing activities are important, but that work--along the ramp slab edges--is not on the project critical path. On the other hand, removing the false work supporting the ramps and cycling the formwork to the upper floors is on the critical path. Once the tightly spaced ramp falsework is replaced with reshores, we can gain access to move materials up and down the ramp--typically accomplished with push carts (aka "cadillacs").

In other words, the project can suffer delays when the approval process that triggers formwork cycling is slowed or stopped while the short tendon elongations are investigated by both the PT supplier and the structural engineer, which is what is happening now. The PT supplier is checking the calibration scenario and is running friction calculations; the structural engineer has been contacted, but has yet to weigh in. We are expecting the engineer to ask us to perform a few "lift-offs" (e.g. re-pull certain tendons until the wedges release, then read gauge pressure on the ram to verify forces in the tendons) and report our findings.

We are looking for guidance from the ASCC Hotline to help us work through this, and to find out if there is a better (and faster) way to resolve short tendon pulls. Please advise.

Answer: You are not alone. Over the years, the ASCC Technical Division has fielded calls from members who have reported that "when it comes to PT... short tendons never seem to come up". As it turns out, there is plenty of industry documentation that describes the problem of short tendon elongations--and possible reasons why--and some solutions. Let's start with the ACI Code.

According to the approved PT calculations prepared by your PT supplier, the 30-foot-long ramp tendons have a theoretical measured elongation of 2.37 inches--or approximately 2 3/8 inches. According to the ACI Code (e.g. ACI 318-19 Building Code Requirements for Structural Concrete) section 26.10.2(e), there are two ways the prestressing force shall be verified: by measured tendon tail elongation, and by the jacking force measured with the gauge of a calibrated stressing ram. For a theoretical measured tendon elongation of 2.37 inches, the 7 percent tolerance is roughly 3/16 inch. The actual gauge pressure will be given by the calibration charts and other equipment documentation that should have accompanied the stressing ram when it was sent to the jobsite.

ACI Code section 26.10.2(f) states "The cause of any difference in force determination...that exceeds 5 percent for pretensioned construction or 7 percent for post-tensioned construction shall be ascertained and corrected, unless approved by the licensed design professional".

Why is the tolerance more "relaxed" for the post-tensioned construction as opposed to pretensioned construction? The answer is given in corresponding Code Commentary section R26.10.2(f) as follows:

"The 5 percent tolerance for pretensioned construction reflects experience with production of those members. Because prestressing reinforcement for pretensioned construction is usually stressed in air with minimal friction effects, a 5 percent tolerance is considered reasonable. For post-tensioned construction, a slightly higher tolerance is permitted. Elongation measurements for post-tensioned construction are affected by several factors that are less significant or that do not exist for pretensioned construction. The friction along prestressing reinforcement in post-tensioning applications may be affected to varying degrees by placing tolerances and small irregularities in tendon profile due to tendon and concrete placement. The friction coefficients between the prestressing reinforcement and the duct are also subject to variation".

Another document that explains the short tendon syndrome comes to us from the Post-Tensioning Institute (PTI) Special Topics Committee. Titled "Short Tendon Elongations, PTI Technical Note No. 16" offers a comprehensive review of the topic, and offers some suggested solutions--including relaxing the tolerances.

A link to the PTI Tech Note 16 is here:

https://www.post-tensioning.org/Portals/13/Files/Pdfs/Education/Technical%20Note%2016.pdf

In similar fashion, another PTI publication prepared by the PTI Unbonded Tendons Committee called "Frequently Asked Questions: Field Elongation Measurements"

offers a thorough explanation of best practices for addressing short tendon pulls.

A link to PTI FAQ No. 6 is here:

https://www.post-tensioning.org/Portals/13/Files/pdfs/Education/FAQ%20no.%206.pdf

As luck would have it, a recent issue (March 2025) of "Structure" Magazine contains an article titled "Best Practices for Post-Tensioning Elongation Records", which has been approved for reprint by the Post-Tensioning Institute (PTI). A link to the article is here:

https://www.structuremag.org/article/best-practices-for-post-tensioning-elongation-records/

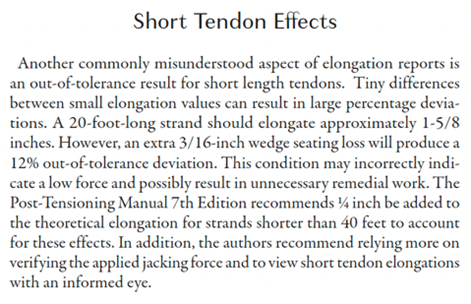

Here's an excerpt from the "Structure" article regarding the issue of short tendon elongations:

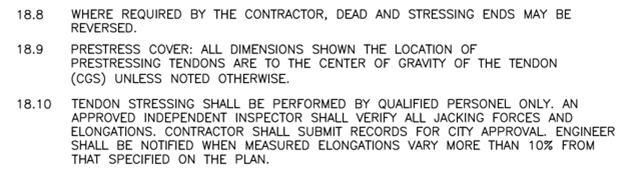

In order to resolve your particular issue, we briefly reviewed your plans, specifications, PT shop drawings, and calculations approved for project use. As it turns out, the construction team (including the project inspector) appears to have overlooked the tolerance specified in the structural General Note 18.10 that will give you some relief--an allowable tolerance of plus/minus 10 percent. See below:

Once you read the technical information via the links given above, you will see that--in addition to lift-offs and additional computer runs--the most sensible course of action is to apply a little engineering judgement and relax the tolerances. This appears to be what your engineer has done by moving the tolerances 3 points in each direction--to plus/minus 10 percent from 7 percent.