Question: We were recently declared the lowest responsible bidder on a reinforced concrete mid-rise municipal building project that features varying amounts of reinforcing steel congestion in the walls that comprise the building's structural frame. Our estimating team bid the job assuming all walls will be formed on both sides and placed from above using the so-called "form-and-pour" method of concrete placement. At the elevator core shear walls, for example, we plan to solve the worst congestion problems with self-consolidating concrete (SCC), proportioned with half-inch coarse aggregate and placed with a concrete boom pump. At other locations, however, the walls are only "lightly congested"--with forming and concrete placement methods yet to be determined.

After the bids had been opened and the bid forms were examined, we could see the shotcrete placing method was not mentioned in any of the bid forms submitted by us--or by our competitors. But--now that we have the job--we are having second thoughts.

Our in-house shotcrete division manager was given an "Issued for Construction" set of structural drawings yesterday. He reviewed the structural details for the walls, and swears all the walls on this project can be successfully shot as long as the shotcrete placing crew provides a limited amount of supplemental vibration to assist with concrete consolidation in the most congested sectors of the walls--typically found at wall end boundary elements--and around openings that require trim steel. Aside from the wall ends and large blockouts, the walls (aside from the elevator core) are typically reinforced with double curtains of #5 bars, 12 inches OCEW (on center, each way). In other words, much of the square footage of each wall is a target-rich environment for shotcrete placement.

Since the construction documents are silent regarding shotcrete, our company owner asked us to submit a proposal to the design team to place certain walls with shotcrete; with the understanding that our supplemental vibration techniques will be demonstrated with preconstruction mockup panels and then used for effect once the project walls go into production.

Based on our limited contact with the design team during the pre-bid process, we have the impression that they have not worked with shotcrete on previous projects. We only had a very short time to do the takeoffs and estimates for what was shown on the drawings. Unfortunately, there just wasn't enough time to consider alternates and float the idea up the stakeholder (and competitor) food chain with pre-bid RFI's.

Does the ASCC Hotline have any information available that we can submit to the project stakeholders to support our proposal? We wish to submit a draft of our plan--including the shotcrete mix designs and an adjusted baseline schedule--in advance of the first construction kick-off meeting to be held at the jobsite two weeks from now. We believe our plan--if accepted--will shave about 3 weeks from the project schedule.

Answer: As it turns out, there is convincing industry backup to support your proposed plan to utilize the "shotcrete with limited supplemental vibration" process of concrete placement.

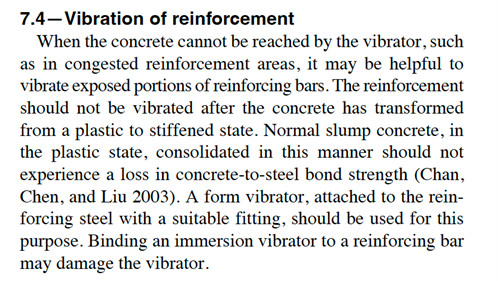

First, no matter what method of placement is used to cast the concrete in place (e.g. "form-and-pour", shotcrete, belt, bucket, Georgia buggy, whatever), ACI 309R-05 Guide for Consolidation of Concrete, section 7.4 describes one method of providing supplemental vibration to assist in the consolidation of concrete in congested areas, namely by touching the exposed reinforcing steel bars with a vibrator. This can be helpful--as long as the concrete is still in a plastic state--as described below:

The suggested technique (above) of using a form vibrator to accomplish consolidation will not work in your situation, since you will only be backforming one side of each wall. As we will see, supplemental vibration techniques used in conjunction with shotcrete require a certain amount of careful artistry on the part of an experienced vibrator operator, coupled with the appropriate pencil-type vibrator and close coordination with the nozzleman.

In addition to ACI 309 section 7.4 (above), a second industry document we recommend you use to support your plan is an article written by fellow ASCC member (and experienced shotcrete nozzleman) Oscar Duckworth titled "Can Supplemental Consolidation Extend the Limits of Shotcrete Placement?" ("Shotcrete" Magazine's "Shotcrete Corner", published by the American Shotcrete Association (ASA) in their Fall 2018 quarterly issue). A link to Duckworth's ASA article is given below:

https://shotcrete.org/wp-content/uploads/2020/05/2018Fal_ShotcreteCorner.pdf

It seems that the vibes you detected from your initial limited contact with the project licensed design professional (LDP) indicate that--in general--the shotcrete process of casting concrete walls in place is relatively new to them. ASCC member Hotline callers have also reported to us over the years that LDP inexperience with shotcrete seems to be a hurdle preventing wider use of the process in their particular geographic construction markets as well.

In that case, Duckworth's article would be an effective document to submit because it not only addresses the immediate topic of supplemental vibration but also presents a crisp and informative recap of the shotcrete process itself--as viewed through the lens of an experienced shotcrete nozzleman--complete with examples and photographs of shotcrete test panels with degrees of reinforcing steel congestion that make them prime candidates for supplemental mechanical vibration.

Here are a few selected excerpts--some paraphrased by the Hotline--from Duckworth's ASA Shotcrete Magazine article:

"Shotcrete is a high-velocity concrete placement method. In thicker concrete sections with heavily congested reinforcement, the impact velocity is significantly reduced as the material travels through the outer layers of reinforcement. Thus, to provide the consolidation needed to fully encase the reinforcement and compact the concrete, many contractors will use a small pencil-type vibrator with a frequency range of 10,000 RPM (or above) to achieve complete consolidation."

"Since freshly placed shotcrete can be easily damaged by vibration, the material must be placed as tightly as possible through proper nozzling techniques. Simply put, the mechanical vibrator is used only to assist--rather than serve--as the primary means of consolidation. The material must be carefully placed with vibration used only to help consolidate any remaining small voids or shadow areas behind obstacles."

"Skilled shotcrete operators focus the vibrator activity only within discrete areas, working carefully to avoid movement of the in-place material outside the vibrator's radius of action. If operated carelessly, vibrators can damage in-place work. Because material being vibrated is not retained within the formwork, over-vibration can cause the fluidized material to flow downward and outward; which can result in cracks, reduction in internal cohesion, or possibly break the bond between the shotcrete, the reinforcement, or the underlying material."

"The use of a mechanical vibrator as a supplementary means to consolidate shotcrete can be an extremely valuable tool to counteract the natural limitations of the shotcrete placement process in congested structural concrete. The key here is that experienced personnel--and properly chosen vibration equipment--must be paired up with high quality nozzling practices."

In addition to the above, we suggest you consider including the relevant shotcrete excerpts from the current ACI Code--e.g. ACI 318-19 Building Code Requirements for Structural Concrete--which incorporated the shotcrete process of casting concrete in place during the last (2019) Code cycle. (ACI 318-19 Chapters 4 and 26, for example, contain most of the relevant shotcrete Code requirements.) In previous years, the ACI 318 Code series had been silent regarding shotcrete; project LDP's had to rely on the IBC (International Building Code section 1908) for shotcrete requirements needed for designs, preconstruction mockups, inspection and acceptance.

ASCC Hotline callers that work in markets where shotcrete use is now routine can tell you that the incorporation of the shotcrete Code requirements (from IBC to ACI 318) certainly played a role in bringing the shotcrete process to the attention of designers, Owners, and local government jurisdictions who otherwise had only limited previous shotcrete exposure--if any at all.

Hopefully, your plan will be accepted and give you a great opportunity to showcase the benefits the shotcrete process can bring to a project.

_____________________________________________________________

Question: We understand that ACI Committee 318 will be publishing a revised Building Code for Structural Concrete in 2025 that will feature changes to the compressive strength test cylinder protocols specified for use in determining acceptance of concrete--specifically the smaller 4 X 8 in. cylinder size specified in ACI 318-19, Chapter 26. What can the ASCC Hotline tell us about the expected Code changes? What exactly are such changes, and what is driving them?

Answer: You are correct. As it turns out, the 4-inch diameter compressive strength test acceptance cylinders are not without their share of controversies, some of which date back to the early 1970's. The latest--and perhaps the final--controversy appears to be nearing resolution when the ACI 318-25 version of the Code is formally issued. For now, we have to depend on the "public comment" version of the proposed ACI 318-25 Code, which was advertised by ACI and reviewed by the public over this past summer as described below. Here's the story.

(N.B.: The current version of "the Code" is titled ACI 318-19 Building Code Requirements for Structural Concrete. When released next year, part of the title will simply be revised to reflect the year of publication e.g. "ACI 318-19" will be updated to "ACI 318-25").

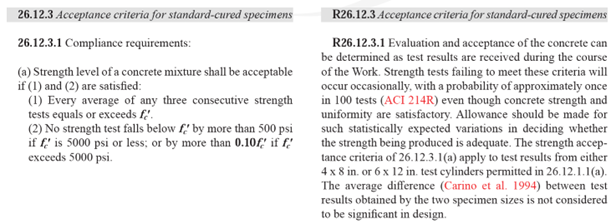

As defined in the current Code, ACI 318-19 section 26.12.1.1, compliance requirements for evaluation and acceptance specimens are as follows: "Evaluation of hardened concrete shall be based on strength tests. A strength test is the average of the compressive strengths of at least two 6 X 12 in. cylinders or at least three 4 X 8 in. cylinders made from the same sample of concrete..."

What is the rationale behind the requirement for three 4-inch cylinders? Why not two? According to the companion commentary (e.g. ACI 318-19 section R26.12.1.1(a)), "The cylinder size should be agreed upon by the owner, licensed design professional, and testing agency before construction. Testing three instead of two 4 X 8 in. cylinders preserves the confidence level of the average strength because 4 X 8 in. cylinders tend to have approximately 20 percent higher within-test variability than 6 X 12 in. cylinders."

During this last 6-year long ACI Code cycle, hundreds of changes to the Code were proposed and balloted by almost twenty ACI 318 subcommittees. A draft version of the proposed ACI 318-25 Code was then advertised by ACI for a 45-day public review and comment period (from 19 May to 2 July 2024). The revised section 26.12.1.1 that appeared in the public comment draft version now states " A strength test is the average of the compressive strengths of at least two 4 X 8 in. or two 6 X 12 in. cylinders..."

The rationale explaining the proposed change from three 4 X 8 in. cylinders to two appears in the draft version of future ACI 318-25 companion commentary section R26.12.1.1(a) as follows: "Recent test data including cylinders prepared in the field, indicate the difference between the within-test variability of tests of 4 X 8 in. cylinders and 6 X 12 in. cylinders is not statistically significant...Accordingly, the Code now permits the use of at least two cylinders for a strength test for either 4 X 8 in. or 6 X 12 in. cylinders."

To date, the Hotline has not heard of any persuasive public comment objections (aka "negatives") to the proposed reduction in number of 4 X 8 in. test cylinders described above. Barring unforeseen events, then, it appears the change from three to two 4 X 8 in. cylinders should be accepted, codified, and become effective when the ACI 318-25 Code document is officially released by ACI. The publication dates are currently slated for January 2025 on the ACI 318 PLUS platform and in hard copy (paper) format to follow in February or March.

________________________________________________________________

Question: Early this year, our company was awarded the reinforced concrete portion of a public works project located just west of the Washington, D.C. metropolitan area. All compressive strength compliance testing for the structural concrete in our scope (e.g. spread footings, grade beams, walls, columns, slabs on ground, and elevated slabs) is by others--a local testing and inspection agency that reports to the Owner's construction manager (CM).

According to our construction documents, the nominal design compressive strength for the structural foundation elements (spread footings and wall footings) is specified as 5000 psi at 56 days. Given that particular strength class, the required testing protocols are listed in our project specifications as follows:

Test specimens must be prepared and handled per ASTM C31/C31M: Standard Practice for Making and Curing Test Specimens in the Field.

Test specimens must be tested per ASTM C39/C39M: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens.

Compressive strength cylinders are to be tested for acceptance at 56 days.

Each set of test specimens consists of 7 each cylinders, tested as follows: 1 cylinder at 7 days, 2 cylinders at 28 days, 3 cylinders at 56 days, and 1 cylinder held in reserve. Applies only when specimens are 4-inch dia. by 8 inches in length.

Each set of test specimens consists of 6 each cylinders, tested as follows: 1 cylinder at 7 days, 2 cylinders at 28 days, 2 cylinders at 56 days, and 1 cylinder held in reserve. Applies only when specimens are 6-inch dia. by 12 inches in length. (Not used on this project).

Frequency of sampling is one set for every 50 cubic yards (CY), each mix, each day; or one set for every 2500 square feet (SF) of wall or slab surface area.

For structural column concrete, every truck load must be sampled.

(Note: regarding the choice of test specimen sizes; who gets to choose? According to ACI 318-19 Commentary section R26.12.1.1(a), "The cylinder size should be agreed upon by the Owner, licensed design professional, and testing agency before construction." In other words, the concrete contractor is not in that particular decision loop).

Placement of the foundation concrete on our project began about 2 months ago. Now, here we are--some two months after our first foundation concrete placement--and the 56-day acceptance compressive strength cylinder test results are starting to come in. This latest batch of Owner agency test reports features two items of concern for us.

The first item of concern is the statement that appears in bold at the bottom of each report: "NOTE: LOW TEST RESULTS". Over the years, of course, our company has received compressive strength test reports on certain projects indicating apparent low breaks. It is fair to say this scenario is routine--an event to be expected, in fact--and certainly no reason for panic waves to ripple all up and down the stakeholder food chain. A recent article that explores this topic in great detail appeared in the February 2022 issue of ACI Concrete International. Titled "Expect Compressive Strength Test Results Less Than Specified Strength on Every Project", the authors explain the statistical basis behind the methodology used to evaluate compressive strength test results and determine contract (and Code) compliance. Authored by a team of ASCC members, the article is available on the ASCC web page at this link:

https://ascconline.org/Portals/ASCC/Expect-Compressive.pdf

The second item of concern is the methodology used by the test agency to calculate and evaluate those results; and then from there--determine compliance.

The Code compliance requirements listed in ACI 318-19 section 26.12.3.1 (see below) are straightforward enough. Tabulating and maintaining a "running average" strength test result spreadsheet is a relatively simple matter for our project engineer to track at the job site.

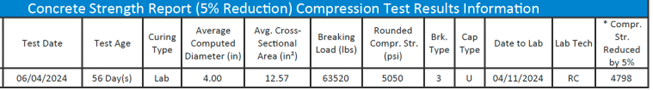

But the test agency on our project has thrown a curve ball on their test reports by adding an extra data column that takes the actual rounded compressive strength test result and then reduces that actual value by 5 percent. See last column in the test report table below titled "*Compr. Str. Reduced by 5%".

In this case, the actual rounded compressive strength of 5050 psi is reduced by 5 percent to 4798 psi. Evidently, the testing agency is reducing (aka "de-rating") the actual strength value simply because 4-inch by 8-inch cylinders were used. In other words, if the test specimens were molded in 6-inch by 12-inch cylinders, the actual, unreduced compressive strength test result would be reported and used to determine compliance.

We have not heard of this methodology before, and do not see such a strength reduction factor in the Code. In fact--just the opposite--as stated in the ACI Code Commentary section R26.12.3.1, shown above. If the difference in cylinder sizes is "not considered to be significant in design", why would the 4- inch cylinder values need to be reduced once the job moves from design to construction? Please advise.

Answer: Great question. The short answer is that this is simply a classic example where local government ordinances overrule requirements given in ACI Codes and Specifications.

As noted above, the Owner's test agency is applying the 5 percent strength reduction factor to comply with local jurisdictional requirements. In your case, the "jurisdiction" is a governmental (County level) entity administered by the Critical Structures/Commercial Building Branch of the Fairfax County, Virginia Building Division. The so-called "5 percent rule" governing the use of 4-inch by 8-inch cylinders is presented in a document prepared by the Fairfax County Critical Structures (FCCS) Branch titled "Special Inspections Program (SIP)" in Section 704 Concrete Testing thusly: "Test results must be de-rated by 5%; i.e., nominal results must be multiplied by 0.95 to obtain the final results." The FCCS SIP Program has been made--by reference--an integral part of your project construction documents.

Although the ASCC Technical Division is familiar with the stringent FCCS protocols and requirements associated with the erection and removal of formwork and shoring in Fairfax County, this was our first exposure to the "5 percent rule" per se. But ASCC Hotline callers know full well that several ACI documents (ACI 117, ACI 318, and others) remind the readers straightaway that the LDP is free to confect specifications and compliance criteria that are more stringent than the traditional and customary "industry standards".

At the same time, of course, it is always the concrete contractor's responsibility to detect the "tighter" specification language clauses and carve-outs and to consider their implications before estimating and pricing the work--and certainly to rinse such items out before signing any binding construction contract.

_________________________________________________________________

Background notes: As all ASCC Hotline callers know, concrete is a natural product with its fair share of idiosyncrasies and controversies. Based on a recent literature survey regarding the 4 X 8 in. cylinders, we drilled deep below the weeds and found the following information worth passing along...

Compressive strength testing is hardly a cut-and-dried proposition. After all, the only way to know the true compressive strength of concrete is to compress it.

In the U.S., compressive strength testing for acceptance is done with either 4 X 8 in. or 6 X 12 in. cylinders. In the U.K., such testing is done with either 4 in. or 6 in. square cubes (100 or 150 mm).

Studies have shown that 2 in. square cubes break up to 15 percent higher than 6 X 12 in. cylinders. On the other hand, 4 X 8 in. cylinders have been reported to break higher than 6 X 12 in. cylinders as well, up to 4 percent higher.

One normalweight concrete 4 X 8 in. cylinder weighs about 9 lbs., while one normalweight 6 X 12 in. cylinder weighs about 30 lbs.

Proponents of the 4 X 8 in. cylinders say the smaller cylinders result in less wear and tear on the compression test equipment. If a cylinder stress of 5000 psi is required, for example, the 6-inch cylinder would have to be loaded to 141,500 lbs., while the 4-inch cylinder would only have to be loaded to 63,000 lbs.

On the other hand, opponents say the lighter cylinders could be subject to mishandling and abuse on the construction site; and that the smaller cylinders will be no cheaper since many test agencies charge a unit rate per cylinder, no matter what its size and no matter if the specimen actually ever gets tested.

The protocols for compressive strength test cylinders are given in ASTM C31 Standard Practice for Making and Curing Test Specimens in the Field. ASTM C31 section 6.1 tells us "the number and size of cylinders shall be as directed by the specifier of the tests. In addition, the length shall be twice the diameter, and the cylinder diameter shall be at least 3 times the nominal maximum size of the coarse aggregate". Furthermore, if the purpose of the cylinders is acceptance testing for specified compressive strength, cylinders shall be 6 by 12 in. or 4 by 8 in.

The key takeaway from the above ASTM C31 excerpt is the limit on coarse aggregate size, since this excludes any mixes that feature 1 1/2-inch coarse aggregate. In some cases, state highway departments and other regional jurisdictions limit the use of 4-inch cylinders to mixes that are proportioned with 1-inch maximum coarse aggregate size.

_________________________________________________________________