Jim Klinger, Concrete Construction Specialist The Voice Newsletter January 2024

Full Disclosure: One of the most valuable concrete industry documents that will ever cross the desk of an ASCC member is ASTM C94: Standard Specification for Ready-Mixed Concrete. Its companion document (prepared jointly in 2014 by the American Society for Testing and Materials (ASTM International) and the National Ready Mixed Concrete Association (NRMCA), see cover shot, below) is titled The User's Guide to ASTM Specification C94/C94M on Ready-Mixed Concrete: 2nd Edition. Worked in tandem, these two documents present and explain the technical background, legal particulars and associated stakeholder responsibilities that surround the materials, manufacture, mixing, delivery, testing, and purchase of ready-mixed concrete. What follows below relies heavily on both the Standard Specification (hereinafter referred to as "ASTM C94") and the User's Guide (aka "The Guide").

___________________________________________________________________________

If you are a concrete contractor doing business here in the U.S., you have little choice but to become fluent in the entire ASTM C94 document--or at least be familiar enough to be able to find what you need, when you need it. As a stand-alone industry standard quality specification, ASTM C94 is neither a quick nor easy read. But thanks to co-authors Daniel and Lobo, the content of ASTM C94 is carefully dissected and explored--section by section--much to the benefit of all project stakeholders and readers of The Guide.

According to The Guide, ASTM C94 is "written to the purchaser or general contractor to allow the owner to identify who is ultimately responsible for the entire concreting operation. ASTM C94 is also written in an attempt to separate the responsibilities of the concrete manufacturing process and product delivery from the overall responsibilities of the general contractor or a concrete contractor. This separation is needed for clarity in a purchase order for concrete or a delivered materials contract whether written or oral."

According to ASTM C94, the term "ready-mixed concrete" is defined as "concrete manufactured and delivered to a purchaser in a fresh state." Accordingly, the term "purchaser" typically refers to the concrete subcontractor who orders concrete on behalf of the owner. In other words--just so we're clear-- the concrete contractor is usually the purchaser.

At the date of this writing, the latest available version of ASTM C94 is designated ASTM C94/C94M-23. On the other hand, the 2014 copyright date of the User's Guide 2nd Edition indicates the document is based on ASTM C94/C94M-13. In other words, there is roughly a 10-year spread between these companion documents (more on that below). If purchased today, ASTM C94/C94M-23 (16 pages) is listed at $69.00, while The Guide (MNL49-2ND-EB, 160 pages) can be purchased from ASTM International in either soft-cover hard copy or in searchable pdf format for $89.00. The Guide is also advertised by NRMCA for purchase at a discounted price of $75.00 for NRMCA members. There are currently no plans for a 3rd Edition of The Guide.

______________________________________________________________________________

Question: We are preparing the agenda for an upcoming preconstruction conference. Our contract scope features the reinforced concrete portion of two identical structural steel office buildings and an adjacent post-tensioned (PT) concrete parking structure. At bid time, the total concrete material purchase quantity was estimated at 43,365 cubic yards (CY), counting shotcrete. Our concrete supplier is still compiling the backup data required by ACI 301 and ACI 318 to support the mix design submittals and will request design team approval to be able to adjust the slump (and possibly entrained air content) in cases where preliminary jobsite testing reveals slump or air test measurements higher than those specified in the construction documents. Any adjustments would be accomplished at the truck by using site-added proprietary ASTM C494 Type "S" (specific performance) slump reducing or air-detraining admixtures. We are hoping to get the proposed admixture product data cut sheets, manufacturer's printed installation instructions (MPII), and safety data sheets included in our first round of mix design submittals, along with any available trial batch performance data. The idea is to have this initial submittal in the design team's hands at least a week before the preconstruction conference. We will also ask the GC to float a preview copy of our mix design submittal to the owner's inspection agency for their use. Our project engineer has reviewed the NRMCA/ASCC Checklist for the Concrete Pre-Construction Conference and found jobsite slump adjustments addressed in Section C-14; but there are only three materials listed as potential permitted admixtures: water, mid-range water reducer (MRWR) and high-range water reducer (HRWR). The water and water-reducers are used to increase the slump, not reduce it. This upcoming project will be the largest we have ever done, both in terms of total concrete cubic yards (CY) and number of different concrete mixes needed--including lightweight concrete (LWC) and shotcrete. We have no experience with such site-added admixtures and want to make sure we understand the jobsite concrete adjustment protocols for slump and air reduction before we walk into the meeting. Please advise.

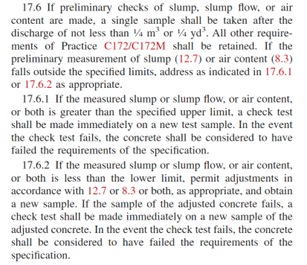

Answer: The protocols are given in ASTM C94, section 17: Sampling and Testing Fresh Concrete. In your case, the applicable section is 17.6.1, since preliminary check testing at the front end of the load is assumed by your supplier to indicate results greater than specified as follows:

Thanks to the authors of The Guide, the supporting rationale is explained as follows:

"A preliminary sample is permitted to be taken after the discharge of at least 1/4 CY. The purpose of the preliminary sample is to permit adjustments to the load if required. This preliminary sample is to be used only for checks of slump or slump flow and air content to determine whether these properties are within the specification limits. The preliminary sample does not need to be very large but should not be the first 1/4 CY discharged. One-fourth cubic yard is not a trivial amount; it is approximately 1000 lb. of material, which must be discharged prior to taking the preliminary sample. Nothing prohibits this discharge into the project. One of the primary purposes of this preliminary sample is to avoid making adjustments to the load for air content and slump after a significant portion of the load has been discharged, which is what occurs when an acceptance sample in accordance with ASTM C172/C172M is obtained. When a sample from the middle of the load is obtained and the slump, slump flow, or air content does not comply with the specification requirements, the quantity of concrete in the truck will be unknown. Making adjustments at a later point will be purely guesswork. The preliminary sample should not be used as the acceptance sample for the molding of strength specimens. It is tempting to proceed with casting strength test specimens when slump or slump flow and air content requirements are met, but this is not acceptable. If the same truck is to be tested, acceptance samples should be obtained at a later point in the discharge and all tests should also be performed on that sample".

So, what happens when preliminary check test results indicate slump or air greater than specified? Section 17.6.2, for example, mentions adjustments for results less than specified.

Once again, the authors of The Guide offer the following instructive commentary:

"No mitigation procedures are currently addressed within ASTM C94/C94M for slump or air contents greater than desired. Thus, no mention is made of the possible use of air-detraining admixtures or slump reducing agents. Such products are available, are often used, and may be desirable by both the producer and purchaser to save the load and keep the delivery of concrete moving. ASTM currently takes no position on the use of these products. The check test on the second preliminary sample is performed before any additional concrete is discharged. If the results of this second test are outside the acceptable limits for the project, the concrete shall be considered as failing the specifications and may be rejected for use on the project or otherwise handled in accordance with project requirements. The purchaser still has the ability to accept the concrete. The purchaser's representative on the job site with the appropriate authority needs to make the judgement as to whether the deviation from the specification requirement is of significance to the requirements of the project and whether the cost and delay associated with rejecting the concrete are justified."

In addition to the consideration of air-detraining or slump reducing admixtures by your project design team, another key takeaway showcased by The Guide (and fair game to be placed on the table at your preconstruction conference) is that concrete cannot be rejected on the basis of a single test of slump or air content--it takes two tests to fail. The concrete can only be rejected if both the first test and the subsequent check test fail. Without two tests, the concrete may be improperly rejected, leading to disputes about who should pay for the rejected concrete. And, as noted in The Guide, the purchaser still has the ability to accept the risk and authorize placement of the concrete anyway, despite the results of two apparent failed tests.

Question: Since there is a 10-plus year spread between publication dates of ASTM C94 and The Guide, does that not render The Guide obsolete?

Answer: Not at all. Although the wheels of progress in the world of industry standards grind slow, it is true that ASTM C94 has been revised since the 2014 publication of The Guide. But the basic framework of ASTM C94 remains largely unchanged. Accordingly, the sheer amount of comprehensive research and backup reference material presented in The Guide help that publication maintain its value.